Toyota pioneered the Toyota Manufacturing System lean pondering observe — a rigorous, data-centric strategy that goals to enhance operations by optimizing enterprise processes and empowering employees to determine and remedy issues — within the Fifties. However lean pondering doesn’t simply apply to manufacturing giants. With the aim of constantly bettering the standard of services and products, the methodology might be priceless to companies of any dimension, throughout sectors and geographies. And with its concentrate on decreasing prices and rising buyer satisfaction, lean pondering can enhance each income and stakeholder well-being.

Using lean approaches amongst small and medium enterprises (SMEs) and throughout the nonprofit sector is rising. It’s a rising a part of our work on the William Davidson Institute on the College of Michigan (WDI). Our staff inside WDI — Efficiency Measurement and Enchancment — applies lean pondering throughout influence measurement and steady enchancment initiatives to unlock monetary and social advantages for our companions. These companions embody each profit-seeking and non-profit companies that leverage enterprise instruments to extend financial and social prosperity in low- and middle-income nations. To take only one instance of this work: In a digital change program led by WDI, we utilized lean pondering instruments to extend pupil survey response charges. Our aim was to make sure that we gathered ample vital suggestions to make adjustments to the course in every subsequent semester (steady enchancment), so as to higher develop cross-cultural understanding and collaboration amongst enrolled college students.

Within the article beneath, we’ll introduce readers to lean pondering and its advantages for SMEs, outline key ideas and commonplace practices that type its central tenets, share in style problem-solving instruments that may assist determine course of efficiencies, and suggest a roadmap for making use of lean approaches in enterprise operations.

An Introduction to Lean Methodologies

Lean pondering is a administration philosophy that may be summed up as “doing extra with much less.” Lean methodologies can provide many advantages to companies. They will improve buyer satisfaction, cut back prices, enhance the standard of services or products and cut back their time-to-market, enhance worker talent growth, and allow corporations to shortly adapt to exterior adjustments. Lean practices ship these advantages by fostering a tradition of steady experimentation in a enterprise, aimed toward maximizing effectivity by creating worth with fewer assets and fewer waste.

Waste is outlined as any motion or step in a enterprise course of that doesn’t add worth to the client. There are eight sorts of waste addressed by lean pondering: defects, overproduction, ready, unused expertise, transportation, stock, movement and further processing. Amongst these, probably the most well-known are: ready (e.g., time spent ready for supplies for manufacturing, data from suppliers, approvals from managers, and so forth.), defects (services or products that don’t meet buyer necessities), and stock (extra merchandise or supplies).

To determine areas of waste, lean pondering establishes a commonplace for each enterprise course of that compares irregular and regular outcomes. It additionally contains procedures to enhance current processes or develop new merchandise/providers successfully and effectively. If the usual doesn’t produce the anticipated end result with minimal waste, lean methodology prescribes a set of practices and instruments to allow the enterprise to experiment with potential options.

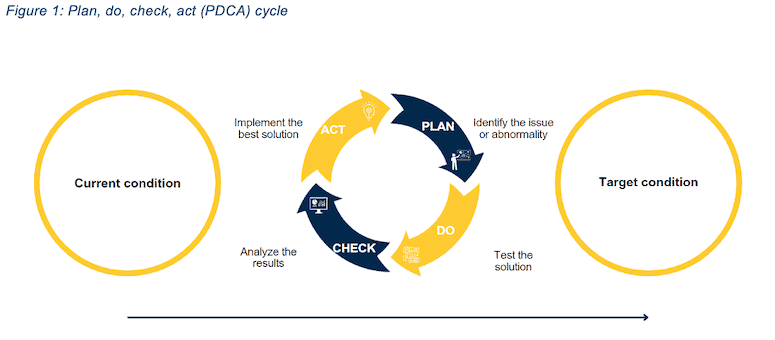

The inspiration of those experiments is the “Plan, Do, Test, Act” (PDCA) cycle. Within the Plan stage, a enterprise runs diagnostics to determine gaps and abnormalities in its processes, defines its targets, and develops an motion plan. Within the Do stage, it strikes into motion, pursuing the targets and duties it has outlined by means of an experiment. That is adopted by the Test stage, through which the enterprise assesses the enhancements it has made by analyzing the outcomes of the experiment. Lastly, within the Act stage, it implements the answer and continues making use of PDCA to determine new potential points. The PDCA cycle is supposed to be repeated time and again for steady enchancment. It supplies a easy and efficient strategy for fixing issues and managing change, whether or not for a complete mission or a small job throughout the mission (See Determine 1 beneath).

Key Lean Pondering Instruments

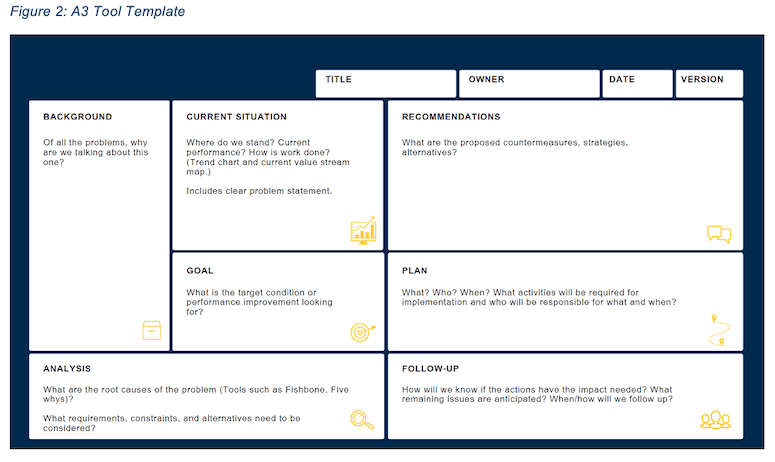

A number of in style lean pondering instruments can be utilized all through the PDCA cycle, together with A3 downside fixing, through which all the important thing details about an issue and its potential options suits on an 11×17 inch piece of paper. The great thing about the A3 strategy is that it tells a concise story a few enterprise downside, laying out a complete plan to unravel it or make a associated enchancment on a single piece of paper (See Determine 2).

The worth of the A3 software lies not within the format, however within the course of and pondering behind it. An A3 strategy will help make the case for change or experimentation, whereas offering a technique to create understanding to result in motion, and inspiring managers and leaders to watch operations and have interaction with workers. Thus, A3 pondering works each as a problem-solving software and a structured course of for growing proficient problem-solvers inside a corporation.

You may be taught extra in regards to the A3 strategy on this recording of WDI’s lean pondering webinar, held in October 2023, through which we stroll by means of an instance of how the A3 software was utilized in a garment manufacturing unit in India. Different in style lean instruments embody the fishbone, 5 whys, worth stream maps (extra useful resource), and course of maps (extra useful resource). Course of maps are additionally mentioned in our webinar recording, the place a colleague from WDI’s Healthcare staff shares how he created a course of map of all of the steps and resolution factors in a watch surgical procedure clinic in Mexico, in an effort to calculate and cut back the corporate’s course of prices.

A Roadmap to Apply Lean Pondering in Your Group

Regardless of its many advantages, lean pondering does current some challenges. For example, it requires a cultural shift due to its concentrate on involving employees — as an alternative of simply administration — in figuring out issues and testing options. It necessitates a dedication to commentary and collaboration, each of which require employees and administration time. It additionally requires that groups keep away from the “blame sport,” through which they spend priceless time making an attempt to assign (or keep away from) accountability for the inevitable shortcomings recognized by the lean strategy.

We acknowledge that lean pondering can generate resistance to vary, however there are methods to handle this. The next roadmap presents small, incremental steps companies can take to start to use lean practices, collect organizational champions to assist these adjustments, and develop buy-in for this technique with management if they’re unfamiliar with the strategy and its value-proposition:

- Begin by figuring out a typical for a key downside or course of. It may be an administrative course of like customer support, or a producing course of. If a typical doesn’t exist, create one based mostly on course benchmarks of prices and time for every step within the course of. You may as well develop benchmarks based mostly on historic context or firm targets. There’s a tendency to need to begin with intensive coaching in your staff on lean pondering, however this could contain a serious funding of money and time. As a substitute, it’s extra priceless to be taught the fundamentals and get began: By figuring out a course of that will profit from such a assessment, you can begin your lean pondering journey, growing your expertise as you apply and observe these methodologies.

- Subsequent, contain the staff in figuring out waste within the course of, by means of using lean instruments. For instance, the staff can create a worth stream map — primarily a flowchart — for the focused downside/course of, and lay out its present steps. Subsequent, the staff can use an A3 problem-solving software to create a speculation for learn how to get rid of the waste it has recognized to create a greater services or products for the client. When making use of these instruments, managers mustn’t sort out the issue themselves; as an alternative, they need to lead a collaborative effort to seek out options along with their groups, making certain staff empowerment and talent growth in any respect employees ranges. To that finish, managers ought to mannequin problem-solving and facilitate and assist the movement of knowledge, particularly throughout groups. Moreover, they need to be sure that a well timed and constructive response is made to employees who determine points, to assist incentivize this key conduct.

- Launch experiments and implement the PDCA cycle. Based mostly on the findings, you may make adjustments to merchandise, providers and operations in real-time. Moreover, sharing the outcomes of the experiments — and highlighting adjustments in key quantitative metrics resembling lead time — can obtain fast wins and construct buy-in for the continued use of lean practices and instruments.

- Determine champions and make the case to management (if wanted), highlighting the worth generated by lean approaches (e.g., increased gross sales, decrease prices, extra engaged workers). Search sustained buy-in and assets for utilizing lean practices.

- Formalize a steady enchancment agenda. Such an agenda will help prioritize the applying of lean pondering to key processes within the firm’s broader technique. The agenda additionally helps be sure that the data gained by means of lean pondering actions is disseminated throughout the firm, making a virtuous loop.

At WDI, we use lean instruments to assist our companions diagnose issues, develop hypotheses, and take a look at and consider these options. We hope this text piqued your curiosity in lean pondering, and that you’re prepared to start out a dialog about this strategy along with your staff. In that case, we’d be glad to debate these practices additional with you. You may attain us at WDI-performancemeasurement@umich.edu.

Yaquta Fatehi is a program supervisor and Heather Esper is the director on the Efficiency Measurement and Enchancment Initiative on the William Davidson Institute (WDI) on the College of Michigan. WDI is NextBillion’s mum or dad group.

Picture courtesy of Jason Goodman